Characterization

After mixing, pressing, and arc melting our nickel-based alloy powders, the resulting metal disks were polished and mounted for characterization.

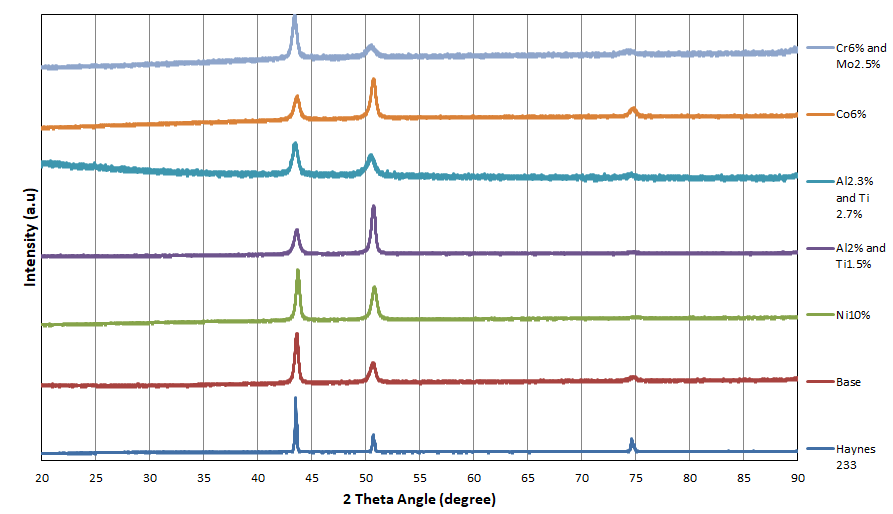

X-Ray Diffraction

The Rigaku Ultima III is a versatile X-ray diffraction system equipped with a high precision horizontal sample stage and a cross beam optics system to permit either Bragg-Brentano para-focusing beam geometries or high-resolution parallel beam with a motor controlled multilayer mirror. The Ultima III diffractometer enables a variety of powder and thin film measurements, including high-resolution powder X-ray diffraction for phase identification, quantitative analysis, lattice parameter refinement, crystallite size, structure refinement, and residual stress. It is also able to perform small-angle X-ray scattering for particle/pore size and shape analysis on the workstations associated with this upgraded Ultima III system.

Our team ran XRD on all samples. We scanned with Cu K-alpha X-ray with λ = 1.5405 Å and scanned from 20 degree to 90 degree with the scan speed of 2 deg/min and step width of 0.01 deg Co6% and Al2%+Ti1.5% has lower first peak and higher second peak in intensity Al2%+Ti 1.5% has lower peak and higher second peak, but Al 2.3%+Ti2.7% has similar peaks to other samples

Scanning Electron Microscopy

The samples were mounted in conductive resin and polished for the SEM. The FEI Magellan 400 XHR SEM was utilized. Its innovative electron-optical elements, beam deceleration, and immersion capabilities allow the Magellan to support flexible imaging operations and refined topographic and materials information. Magellan enables users to explore further into smaller and finer details with its flexibility and ability to observe nanoscale surface details, particles, and material interfaces and analyze chemical information. SEM results coming soon